| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Bag/Bags |

| Delivery Time: | 35 Days |

Basic Info

Model No.: WBB-3

Type: Special Structure of Blow Molding Machine

Raw Material: PET

Making Method of Parison: Stretch Blow

Automation: Automatic

Computerized: Computerized

Certification: CE

Additional Info

Packaging: Wooden Box

Productivity: 3000BPH

Brand: Winiber

Transportation: Ocean

Place of Origin: China

Supply Ability: 10 Sets/Month

HS Code: 8477309000

Port: NINGBO,SHANGHAI

Product Description

Water Bottle Molding Machine is used to blow bottles from PET preform whioch can be bought from the market directly or use our PET injection machine and PET preform mould to produce by customer himself.

We will help customer to design the bottles shape basing on his requirement before making bottle mould.

We will suggest the preform weight basing on the bottle shape and type.

Application: Food, oil, carbonated drinks, mineral water, alcohol, medicine, chemical etc.

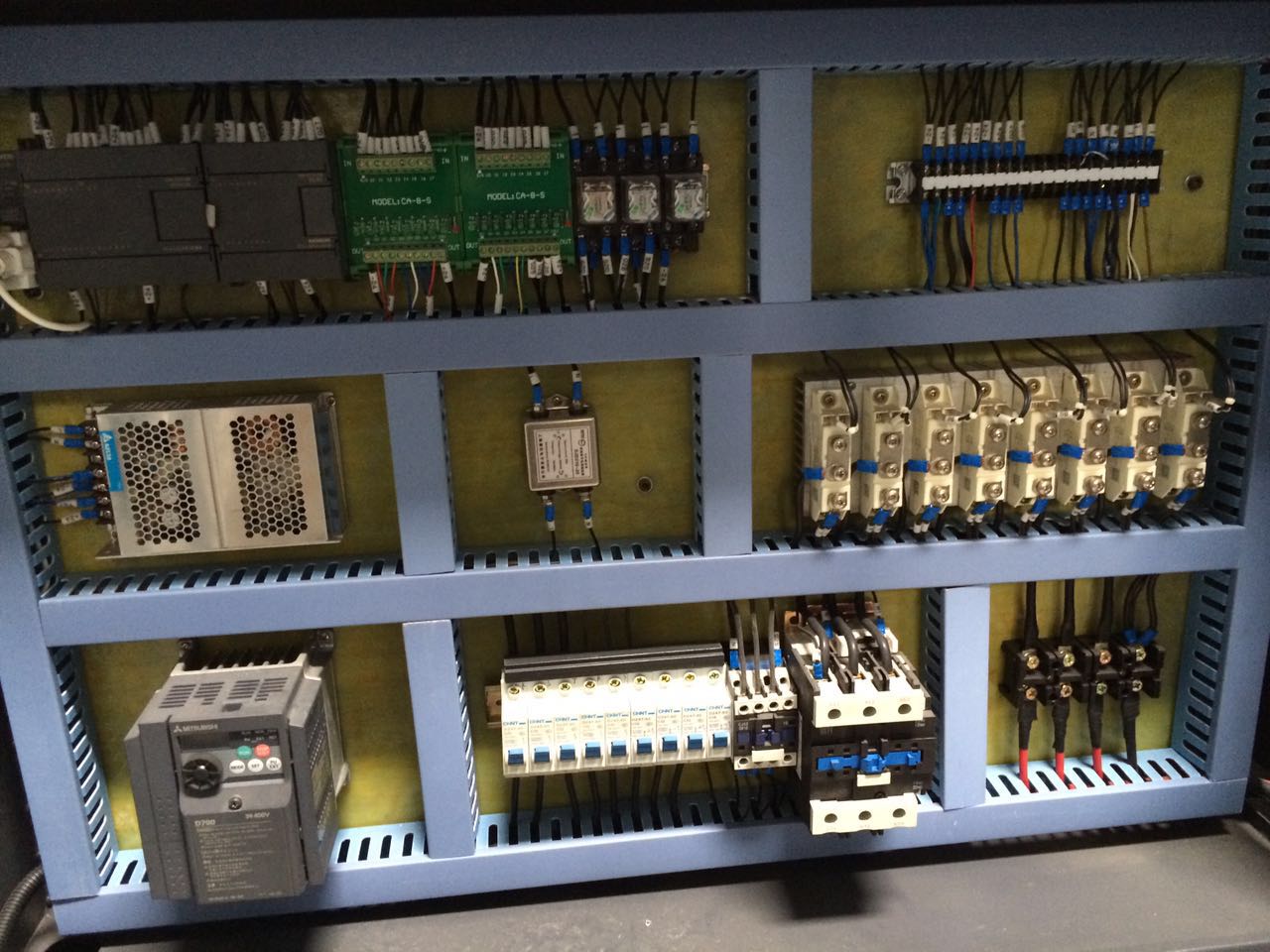

.Adopt human-computer interface to control the whole working procedures, auto-loading, auto blowing, auto dropping. Action cylinders are all assembled with magnetic conduction switches. Connect with PLC to control every step and test every cylinder. Next action will continue after the former step done. If former step is not finished, alarm automatically and do not work. PLC displays problem position.

.Fast Speed, accurate position, smooth action.

.According to special demand, adopt cross double crank pressed clamping, with strong clamping force. Mould open stroke can be adjustable according to the bottle size to save time.

.Far infrared heater lamps have strong penetrations, preform are heated uniformly while rotating, PLC or electronic pressure adjustor controls each group temperature separately.

.particular pre-heater design makes preform close while heating. Change space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

.The air supply system consists of slight blow, high pressure blow, low pressure actions, to supply enough air for different products.

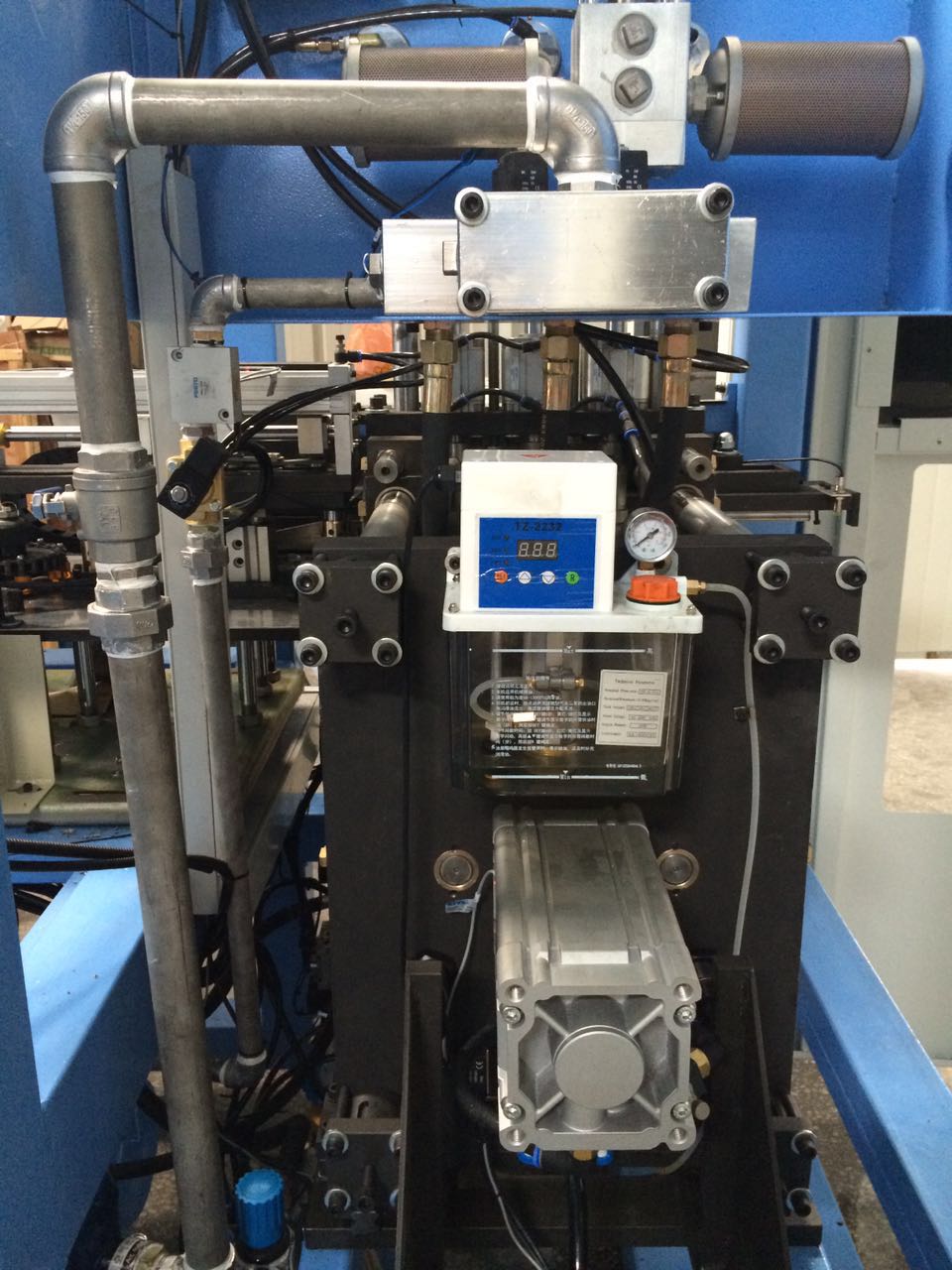

.Connecting rod automatic lubrication oil device protects the machine well.

.Production workmanship process is fully automatic to make best quality and pollution-free. It holds less investment, high efficiency, easy operation, simple repir, safety etc.

| ITEM | UNIT | WBB-3 | WBB-4 | |

| PRODUCT | Theoretical output | Pcs/hr | 3300 | 4500 |

| Max. Volume | L | 1.5 | 1.5 | |

| Max. Height | MM | 360 | 360 | |

| Max. Diameter | MM | 105 | 105 | |

| MOLDING | Number of Cavities | / | 3 | 4 |

| Mould Plate Dimension(L×H) | MM | 430×360 | 600×360 | |

| Mould Thickness | MM | 188 | 188 | |

| Mould Opening Stroke | MM | 110 | 110 | |

| ELECTRICAL | Power |

|

220-380V/50-60HZ | 220-380V/50-60HZ |

| Total Power | KW | 18 | 25 | |

| Heating Power | KW | 15 | 22 | |

| AIR SYSTEM | Operation Pressure | Mpa | 0.8-1.0 | 0.8-1.0 |

| Action Air Consuming | M³/min | ≥1.6 | ≥1.6 | |

| Blowing Pressure | MPA | 2.6-4.0 | 2.6-4.0 | |

| Blowing Air Consuming | M³/min | ≥2.4 | ≥3.2 | |

| MACHINE | Main Body Dimension(L×W×H) | M | 2.7×1.45×2.5 | 3.4×1.9×2.5 |

| Main Body Weight | KG | 2000 | 2600 | |

| Preform Autoloader (L×W×H) | M | 1.9×1.9×2.2 | 1.9×1.9×2.2 | |

| Preform Autoloader Weight | KG | 200 | 200 | |

Factory some machine showing

Inside Structure

Automatic Lubrication Device

Heating System

Electronic

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, PET preform mould, automatic PET blowing machine, Water treatment system, Filling machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Contact Person: Wini Zhou

Phone:86-0577-83531938

Fax:

Address: HIGH-TECH BUSINESS INCUBATOR, XINYE ROAD, BINHAI NEW DISTRICT, PINGYANG, WENZHOU, ZHEJIANG, CHINA,Wenzhou,Zhejiang

Sweep wechat

© 2019 CHINA WAY. All Rights Reserved. WENZHOU WINIBER MACHINERY EQUIPMENT CO., LTD., Inc. All rights reserved. site map. sitemap.html