| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 35 Days |

Basic Info

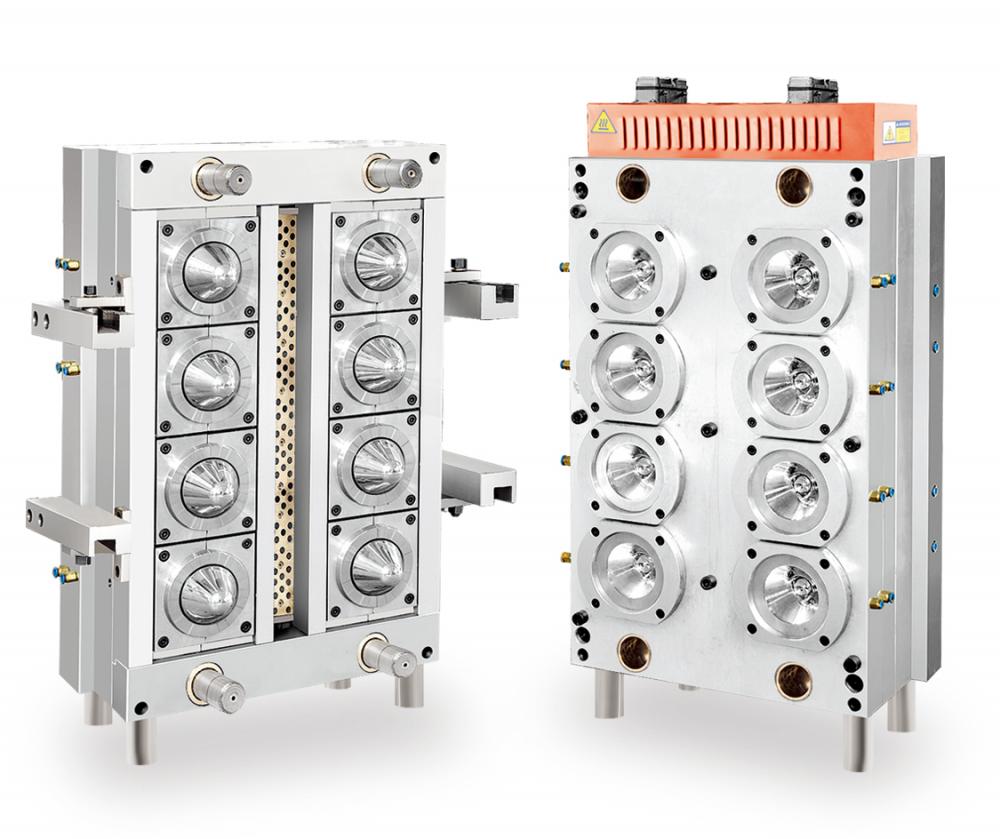

Model No.: 6 Cavity

Material: Stainless Steel

Aluminium: Injection Mould

Gate Type: Pinpoint Gate

Runner System: Hot Runner

Cavity Quantity: 4

Customized: Customized

Additional Info

Packaging: Wooden box

Brand: Winiber

Transportation: Ocean

Place of Origin: China

Supply Ability: 10 Sets/Month

Port: NINGBO,SHANGHAI

Product Description

Application: PET Jar Injection Preform mold is installed on injection machine and used for producing preforms, such as 5 gallon preforms, wide mouth preforms , bottled water preforms.

|

Name

|

Description

|

|

Preform type

|

without injection tail, no need cut

|

|

Runner type

|

hot runner valve gate

|

|

Core, cavity and neck material

|

S136 steel (46-50HRC)

|

|

Mold base

|

chrome plated P20 (anti-rust)

|

|

Hot runner Heater brand

|

Germany hotset

|

|

Cycle time

|

18 to 23 s

|

|

Off-center control range

|

+/-0.05mm

|

|

Mold structure

|

self lock by each cavity; demoulding automatically.

|

|

Mold guarantee

|

5 million shots

|

|

Manufacturing time

|

30 to 50 days

|

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, PET preform mould, plastic bottle blowing machine, Water treatment system, Filling machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Contact Person: Wini Zhou

Phone:86-0577-83531938

Fax:

Address: HIGH-TECH BUSINESS INCUBATOR, XINYE ROAD, BINHAI NEW DISTRICT, PINGYANG, WENZHOU, ZHEJIANG, CHINA,Wenzhou,Zhejiang

Sweep wechat

© 2019 CHINA WAY. All Rights Reserved. WENZHOU WINIBER MACHINERY EQUIPMENT CO., LTD., Inc. All rights reserved. site map. sitemap.html